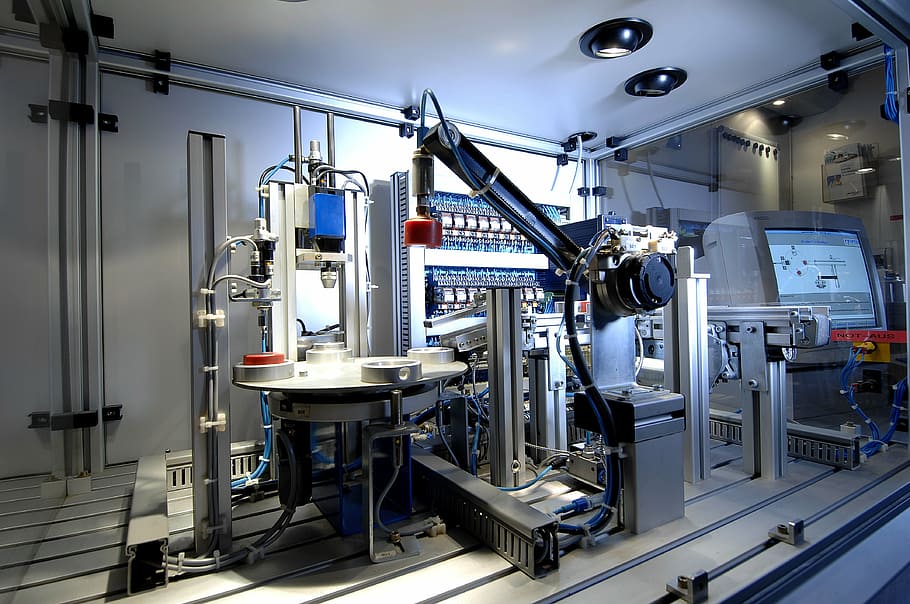

Up-to-date screw capper machines can come in a range of forms. They are generally based upon the sort of cap that’s being used and the level of hands-free operation needed. If production needs get to a particular amount or degree, an auto capper ends up being a complete necessity, yet even for reduced or medium manufacturing facilities, these machines provide even more advantages.

Automating tedious tasks

Non-automated capping can be a tedious job, however, for smaller sized packagers as well as start-up business, it may appear like one of the most cost-efficient and also best option offered. However, capping machines been available in various degrees of computerization for different kinds of operations. It is feasible to conserve cash, time and also even deterioration to the hands by utilizing semi-automatic or automated capping equipment.

How this affects capping

Capping is necessary in ensuring item quality, security and quality. Nevertheless, very few recognize the vital duty that force screening plays and also factors which impact the total accuracy.

Today’s production operations are really concerned with loosened or removed caps which will plainly impact product quality, item stability, shelf-life as well as potentially leak.

Security is of special worry, since wetness delicate or pressurised items need that the integrity of the container fastener as well as seal be maintained.

Loose/stripped caps can bring about both plan and also product issues as the escape of nitrogen in non-carbonated drinks or co2 in sodas or supplement of wetness to a completely dry item can create impurity, discoloration, or substantial adjustments in potency/taste. This can affect the quality of the product.

To maintain/improve process control, it is extremely vital to check the closure honesty continually. For this purpose, there are various torque screening devices offered on the marketplace. However it is hardly ever pointed out that stopper integrity examination results are influenced by a number of factors.

In the past, cap torque testing was as simple as getting a container from the production line and manually examining exactly how limited the cap really felt. As a result of the intuitive feeling of cap rigidity, gradually, the sector shifted toward utilizing much more unbiased measurement devices.

Exactly How Can Capping Machines Advantage Your Company?

Capping machines can not just conserve time, however they can improve the procedure of positioning caps on containers as well as having items all set for delivery. As an example, instead of having to by hand arrange caps or manually area as well as tighten caps, you can let a device do all the work for an uniform, constant result. If your vessels need plugs and also not correct lids, there are likewise machines that can deal with that work, such as automatic upright wheel pluggers. Conserve time and create even more consistent packaging with computerized equipment. Add in an item at once, or buy an entire system at the same time– whatever your budget allows.